SPREADRITE

Increasing Accuracy and Automating Belly Dumps

Need for Spreadrite

Over Dump Effects

Time – slowdowns are caused by the hopper on paving operations overflowing due to too much material getting dumped, sometimes requiring a skid steer to move material around. This slows down the entire operation and can cause many waiting trucks to backup.

Cost – Dumping too much gravel or other materials increase the cost of material for a job. It could also cause need for rework if gravel thicknesses are out of specifications.

Under Dump Effects

Road Quality – lack of material can lead to imperfections in the material exiting the hopper and stoppages can cause bumps in the final road.

Training – It can be difficult for new workers to dump the perfect amount of material when starting on the job, taking time to learn the needed skills.

Our Innovation

SPREADRITE

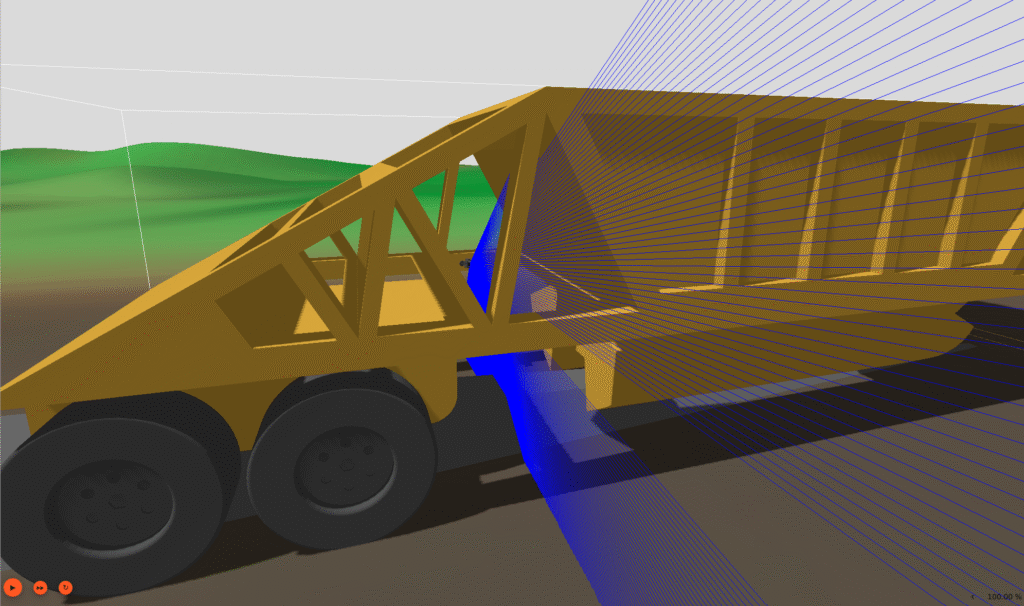

Spreadrite is a display and a sensor array that mounts onto a belly dump trailer and connects into the wiring of the trailer. The sensors detect how much material is getting dumped, the display allows for user input and show a visual output to the user, while the controller inside enables automated dumping.

SPREADRITE saves companies money by reducing material costs with more accurate dumps, while also saving time by minimizing the amount of adjustment that material needs after a dump. Lastly, SPREADRITE makes it easier for new workers to master dumping belly dump trailers.

Features

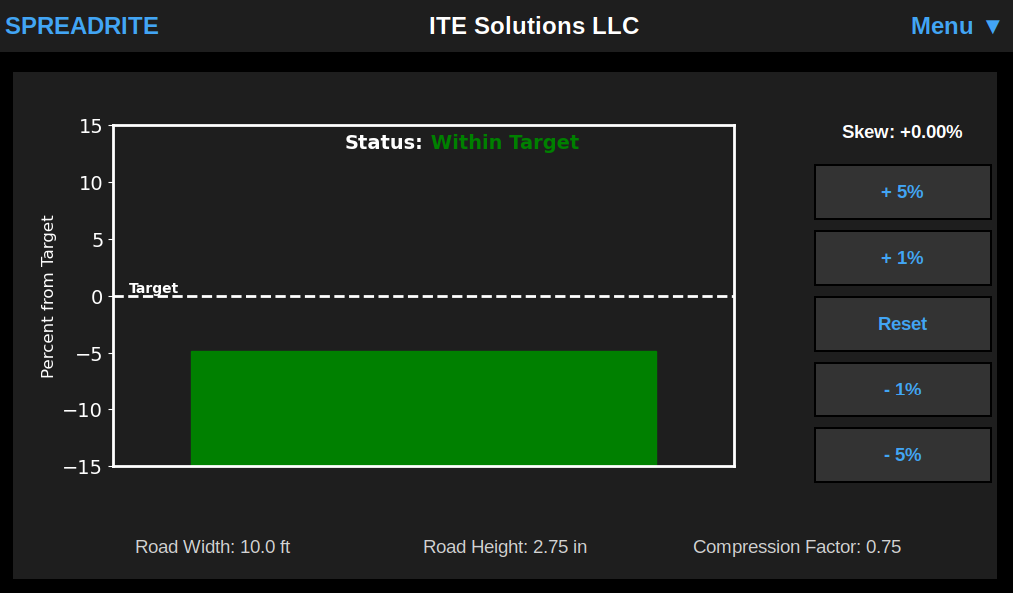

SPREADRITE can operate in indicate mode shown below or in automatic mode. Numerous road specifications can be adjusted and a correction or skew factor can be applied to allow operators to make on the spot adjustments to its output.

Technology

Our patent pending technology uses advanced control algorithms and a lightweight reinforcement learning mechanism to ensure SPREADRITE can adapt to whatever trailer it is thrown onto.